The use of gaylord shipping boxes is evolving as businesses seek sustainable packaging solutions. According to a recent report by Smithers Pira, the global eco-friendly packaging market is projected to reach $500 billion by 2026. Companies are under pressure to reduce their environmental footprint. Gaylord shipping boxes offer a viable option due to their recyclable and reusable nature.

In 2026, the demand for gaylord shipping boxes is expected to increase. Many industries are looking for efficient ways to minimize waste. For instance, 65% of manufacturers report using recycled materials in their packaging strategies. This trend highlights the shift toward sustainability, yet challenges persist. Not all gaylord shipping boxes are created equal, and the sourcing of materials varies significantly.

Moreover, innovation in design and materials is crucial. Companies must educate themselves on the best practices for utilizing gaylord shipping boxes effectively. As sustainable options grow, some organizations struggle to find adequate resources. Balancing cost with sustainability can be difficult. Reflecting on these issues is essential for progress in sustainable packaging solutions.

The current landscape of Gaylord shipping box usage reflects a growing focus on sustainable packaging solutions. Many businesses now prioritize eco-friendly materials. This shift is driven by both consumer demand and regulatory pressure. Gaylord boxes, often made from recycled materials, play a vital role in this narrative. They are large, sturdy, and reusable, reducing the need for multiple smaller boxes. However, not all companies fully embrace these options.

Despite the benefits, some challenges persist. Not every business is ready to make this transition. The upfront cost of switching to sustainable materials can be daunting. Additionally, some organizations remain unaware of the long-term savings associated with using Gaylord boxes. Misconceptions about their strength and durability can lead to resistance. Balancing cost-effectiveness with sustainability is still a work in progress.

Moreover, there is a need for continuous education on best practices. Training employees on the benefits of using Gaylord boxes is essential. The industry must collectively address these gaps. Collaboration between manufacturers, retailers, and consumers is crucial to promote wider adoption. Only through these efforts can we fully realize the potential of Gaylord shipping boxes in sustainable packaging.

The trend of using innovative materials for Gaylord shipping boxes is gaining attention. These boxes play a crucial role in sustainable packaging solutions. Many companies are exploring biodegradable options. These materials break down naturally, reducing waste. Additionally, recycled content is being integrated into box designs. This promotes a circular economy within the shipping industry.

Tips: Always consider the source of your materials. Opt for suppliers who prioritize sustainability. Evaluate the effectiveness of different materials. Not all eco-friendly options fit every purpose.

It's vital to keep testing these materials. Some may look good on paper but fail in real-world applications. For example, while plant-based plastics are an exciting option, they often need careful handling. Regular feedback from users can help refine product choices. Understand that sustainability is a journey, not a destination. Keep pushing for better solutions.

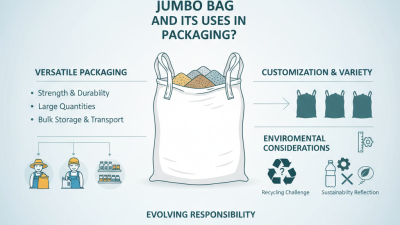

This chart depicts the projected trends in the usage of Gaylord shipping boxes made from eco-friendly materials by 2026. The focus is on the adoption of sustainable materials, increased recyclability, and reduced carbon footprint.

Technological advances are reshaping the landscape of Gaylord box efficiency. Smart sensors are now integrated into these boxes. These sensors track weight and volume, optimizing space during shipping. This data helps reduce waste and enhance sustainability. Companies can monitor inventory levels in real-time. This innovation limits overpacking and ensures better resource management.

Automation in packaging lines also plays a crucial role. Automated systems now handle Gaylord boxes precisely. They improve speed and accuracy, reducing human error. Despite these advancements, some challenges remain. Not every facility is equipped to integrate new technology seamlessly. Training staff to adapt can be a hurdle.

Additionally, there is an ongoing need for sustainable materials. Many Gaylord boxes still use traditional materials. The shift towards fully recyclable substances is slow. While innovations exist, gaps in performance testing need attention. Striking a balance between efficiency and sustainability remains an ongoing challenge.

The market is evolving. Gaylord boxes are becoming essential for sustainable packaging solutions. Their design is influenced by environmental concerns. Recyclable materials are now crucial. Many companies seek eco-friendly options. Sustainability drives innovation in Gaylord box functionality.

Customization is key. Companies want tailored solutions. Flexible sizes and shapes are becoming popular. This allows for better inventory management. Adapting to specific needs enhances efficiency. However, not every design meets these criteria. Failing to consider material quality can lead to issues.

As we look ahead to 2026, Gaylord shipping boxes are poised to play a pivotal role in sustainable packaging. According to recent industry reports, nearly 70% of companies are prioritizing sustainable materials in their supply chains. This shift is not just beneficial; it’s becoming essential. Gaylord boxes, often made from recycled content, align well with these environmental goals.

Innovative designs enhance functionality while reducing waste. Many manufacturers are testing lightweight structures that minimize material use. However, challenges remain. The durability of these lightweight options can sometimes fall short in rigorous shipping conditions. Striking a balance between sustainability and performance is key.

Moreover, the push for circular economy practices is critical. Reports indicate that only 30% of shipping materials are currently recycled. Businesses need to re-evaluate their usage of Gaylord boxes in this context. Are they reusing boxes effectively? Are they engaging in proper recycling practices? Addressing these questions can lead to better implementation of sustainable practices in the shipping industry.

| Trend | Description | Impact on Sustainability | Projected Growth (%) |

|---|---|---|---|

| Use of Recycled Materials | Increased use of recycled paper and cardboard in Gaylord boxes. | Reduces waste and carbon footprint. | 15% |

| Biodegradable Coatings | Incorporation of biodegradable coatings for enhanced protection. | Improves disposal processes and reduces landfill impact. | 20% |

| Streamlined Design | Design innovations for reduced material usage while maintaining strength. | Lowers resource consumption and shipping costs. | 10% |

| Digital Printing on Boxes | Utilization of digital printing technology for customization. | Reduces waste from excess inventory and promotes reuse. | 25% |

| Returnable Packaging Solutions | Development of models for reusable Gaylord boxes. | Significantly cuts down on single-use packaging and waste. | 30% |

Copyright 2025 © Custom Packaging Products | All Rights Reserved